- Essential Maintenance and Refueling Guide for Centerless Grinders

- Essential Maintenance and Refueling Guide for Centerless Grinders

- Essential Maintenance and Refueling Guide for Centerless Grinders

- Steel Peeling Machines: Advantages and Applications

- Why Choose Mingcheng Peeling Machine? Boost Production Efficiency and Create Dual Profits

- Metal Materials and Their Development Trends

E-mail:liu@mingchenggroup.com

Phone:+86 13322202758

QQ:605712576

Address:No. 20, Gangwan Street, Zhongshan District, Dalian City, Liaoning Province

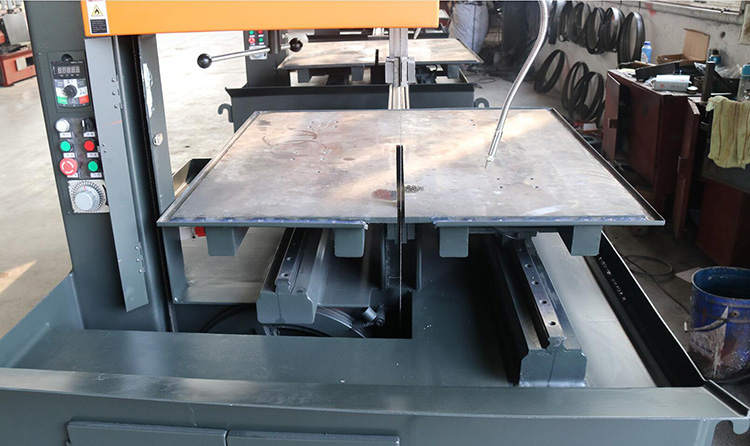

Double-Column Horizontal Band Saw: Precision Metal Cutting

The double-column horizontal band saw machine is an advanced sawing tool designed for cutting various metal materials using a ring band saw. With a robust design and reliable performance, this machine is ideal for diverse applications, ensuring precision, efficiency, and stability. We offer a range of band saw machines suitable for different industries, providing global customers with the right solution for their metal cutting needs.

Scope of Application

Scope of Application

The double-column horizontal band saw machine is primarily used for cutting a wide range of metal materials, including carbon structural steel, low alloy steel, high alloy steel, special alloy steel, stainless steel, and acid-resistant steel. Its versatility and reliable performance make it a valuable tool across multiple sectors that require efficient and precise metal cutting.

Classification

Classification

Based on structure, band saw machines are classified into two types: horizontal and vertical. The horizontal version further divides into scissor type, double-column, and single-column machines. Depending on the operational method, these machines can be manual, which is economical with manual feeding and cutting, or automatic, providing greater efficiency.

Moreover, regarding automation, they can be categorized into semi-automatic, which involves manual feeding, and fully automatic, which allows for automatic feeding and cutting. Additionally, based on cutting angle requirements, there are angle saw machines capable of 90-degree and 45-degree cuts, as well as no-angle machines designed specifically for 90-degree vertical cutting.

System Functions

System Functions

The hydraulic transmission system of the double-column horizontal band saw machine comprises a hydraulic circuit with pumps, valves, cylinders, oil tanks, pipelines, and other components. Under electrical control, this system manages the lifting and lowering of the saw beam and workpiece clamping. The feed speed can be adjusted steplessly using a regulating valve, accommodating the requirements for cutting different materials.

The electrical control system includes a control circuit made up of an electrical box, control box, junction box, travel switch, and electromagnet. This system controls the rotation of the saw blade, the movement of the saw beam, and workpiece clamping, ensuring smooth, accurate cutting cycles according to specific work procedures.

Lubrication System

Lubrication System

Proper lubrication is essential for maintaining the machine's performance. Before starting, oil must be added to all lubrication points, including the wire brush shaft, worm gear box, active bearing seat, worm bearing, and the sliding surfaces of the lifting cylinder and movable vise clamping screw. The worm gear box, containing a worm and worm gear, uses a No. 30 oil bath. Oil should be replenished via the upper oil plug hole, and the oil level must be maintained between the upper and lower limits when the saw beam is at its lowest position.

Initially, the oil should be changed after one month of use and subsequently every 3-6 months, with an oil drain plug provided at the bottom of the worm gear box for easy maintenance.

Structural Features

Structural Features

The double-column horizontal metal band saw comprises several key components, including the base, bed, columns, saw beam, transmission mechanism, guide devices, workpiece clamping units, tensioning devices, feed racks, and hydraulic and electrical control systems. The hydraulic transmission system facilitates smooth and controlled movement, while the electrical control system ensures precise cutting cycles.

Main Features

Main Features

The cutting speed of the double-column horizontal band saw machine is hydraulically controlled, allowing for stepless adjustments to match the requirements of different materials. The guide block structure is scientifically designed, which extends the life of the saw blade and ensures durability. The double-column structure provides enhanced stability during operation, resulting in smooth, precise cutting.

Moreover, the machine is engineered to deliver accurate and stable cuts, making it ideal for complex metal cutting tasks. The workpiece clamping is hydraulically powered, ensuring easy and secure clamping, which simplifies the overall cutting process.

Why Choose Us?

Why Choose Us?

With over ten years of experience in the industry, we specialize in providing high-quality double-column horizontal band saw machines and other industrial solutions. Our commitment to quality ensures that you receive the best products tailored to your specific industrial needs.

Each of our machines comes with a comprehensive one-year warranty for peace of mind. Additionally, our dedicated customer service team is available around the clock to provide assistance and answer any questions you may have.

We cater to clients worldwide, delivering advanced machinery solutions wherever you are. Choose us as your trusted partner for all your industrial sawing needs, and contact us today to learn more about our products and services.

- Previous:Introduction to Automatic Straightening Machine

- Next:Prevent Rust and Moisture in Centerless Lathe Machines

-

2023-09-19How The Round Steel Peeling Machine Works?

-

2023-09-19Round Steel Peeling Machine