- Essential Maintenance and Refueling Guide for Centerless Grinders

- Essential Maintenance and Refueling Guide for Centerless Grinders

- Essential Maintenance and Refueling Guide for Centerless Grinders

- Steel Peeling Machines: Advantages and Applications

- Why Choose Mingcheng Peeling Machine? Boost Production Efficiency and Create Dual Profits

- Metal Materials and Their Development Trends

E-mail:liu@mingchenggroup.com

Phone:+86 13322202758

QQ:605712576

Address:No. 20, Gangwan Street, Zhongshan District, Dalian City, Liaoning Province

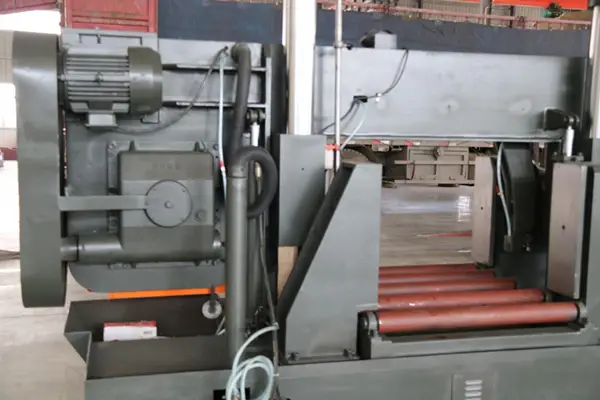

1. Product working principleLarge Angle Band Saw Machine H Steel Cutting Special

1. Product Working Principle:

The Large Angle Band Saw Machine H Steel Cutting Special utilizes advanced CNC technology for precise metal cutting. Through precise guides and transmission systems, the machine achieves accurate cutting operations. The high-speed rotation of the saw blade, coupled with adjustments to the linear speed and guide device position, allows for the adaptation to the cutting needs of various metal materials.

2. Product Features:

- High Efficiency: Offers efficient cutting capabilities for quick completion of tasks involving large amounts of metal materials.

- High Precision: Ensures cutting accuracy and stability through precise guides and transmission systems.

- Strong Adaptability: Equipped with various saw blades to meet the cutting needs of different hardness and types of metal materials.

- Easy to Operate: User-friendly design reduces training costs and time.

3. Application Scenarios:

Widely used in industries requiring cutting and processing of metal materials, including steel plants, metal products factories, automobile manufacturing, and the home appliances industry. Applications include cutting and processing H-beams, automobile parts, and various metal materials in the mentioned industries.

4. Why Choose Large Angle Band Saw Machine for H Steel Cutting:

- High Efficiency: Quick completion of cutting tasks for large amounts of metal materials.

- High Precision: Ensures cutting accuracy and stability.

- Easy to Operate: Simple and fast operation reduces manual operation costs and time.

- High Reliability: Constructed with high-quality materials and parts for stability and durability.

- Service Support: Comprehensive after-sales service and technical support for timely assistance during use.

5. Differences from Similar Machines:

- Structural Optimization: Adopts advanced CNC technology with a compact structure and easy operation.

- High-Performance Transmission System: Utilizes a helical gear reducer for stable and precise cutting operations.

- Precision Guide Device: Employs hydraulic vise and guide arm for cutting accuracy and stability.

- Multiple Saw Blade Options: Equipped with various saw blades to adapt to different metal materials.

- Easy Operation: Features touch screen or control panel operation for convenience.

- Intelligent Control: Equipped with an advanced control system for automatic control and intelligent management.

- Environmental Protection and Energy Saving: Incorporates low noise design and energy-saving technology to reduce environmental impact.

6. Product Parameters:

- See the provided table for specific parameters of Large CNC angle band saw machines.

| parameter | Large CNC angle band saw machine DTJ1000 | Large CNC angle band saw machine DTJ1250 | Large CNC angle band saw machine DTJ1800 |

|---|---|---|---|

| Product model | DTJ1000 | DTJ1250 | DTJ1800 |

| Sawing capacity(mm) | 1000WX500H, with 0-45° bevel cutting function | 1250WX600H, with 0-45° bevel cutting function | 1800WX700H, with 0-45° bevel cutting function |

| Minimum cutting(mm) | 200Wx100H | 200WX100H | 300x100 |

| Band saw specifications (mm) | 8800X67X1.6 | 12500X67x1.6 | |

| Belt line speed (m/min) | 20-100 frequency conversion stepless speed regulation | 20-100 frequency conversion stepless speed regulation | 20-100 frequency conversion stepless speed regulation |

| Saw band tension | Hydraulic | Hydraulic | Hydraulic |

| Working feed method | Hydraulic stepless speed regulation (parametric) | Hydraulic stepless speed regulation (parametric) | Hydraulic stepless speed regulation (parametric) |

| Main motor power (kw) | 11.0, 380v, 50hz | 15.0, 380v, 50hz | 15.0, 380v, 50hz |

| Hydraulic motor power (kw) | 5.5, 380v, 50hz | 5.5, 380v, 50hz | 5.5, 380v, 50hz |

| Water pump motor power (w) | 370, 380v, 50hz | 370, 380v, 50hz | 370, 380v, 50hz |

| Work clamping method | Hydraulic vise (two groups), each can operate independently | Hydraulic vise (two groups), each can operate independently | Hydraulic vise (two groups), each can operate independently |

| Angle adjustment method | Parametric control | Parametric control | Parametric control |

| Inclination angle between the saw blade and the horizontal plane of the bed (°) | 3-5° | 3-5° | 3-5° |

| Main transmission mode | Helical gear reducer | Helical gear reducer | Helical gear reducer |

| Workbench carrying capacity (T) | 15.0 | 15.0 | 15.0 |

| Rotation angle error (°) | ≤±±0.2° | ≤±±0.2° | ≤±±0.2° |

7. Inquiry Guidance:

For inquiries about the Large Angle Band Saw Machine dedicated for H steel cutting, please contact customer service or send an inquiry via email. Detailed product information, quotations, and high-quality after-sales service will be provided to facilitate collaboration towards a better future.