- Выравниватели натяжения: передовые решения по выпрямлению

- Tension Levelers: Advanced Straightening Solutions

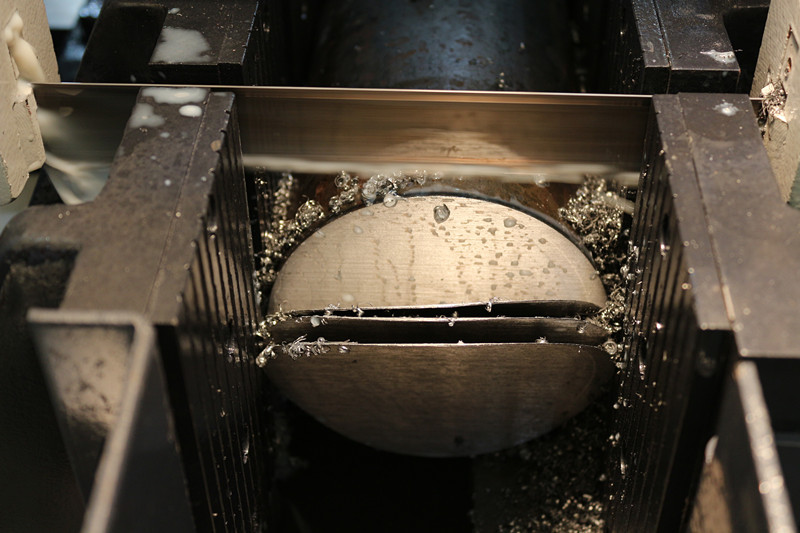

- CNC Sawing Machines: Revolutionizing Precision Cutting

- Industrial Lubrication for Parallel Roller Straighteners

- Double-Column Band Saw: Design, Features, and Applications

- Common Defects in Centerless Grinding

E-mail:liu@mingchenggroup.com

Phone:+86 13322202758

QQ:605712576

Address:No. 20, Gangwan Street, Zhongshan District, Dalian City, Liaoning Province

Working principle: The G-Series multifunctional pulley vertical band saw adopts

Working principle:

The G-Series multifunctional pulley vertical band saw adopts an advanced pulley structure, uses a DC motor to control the feed speed, and adjusts the speed through frequency conversion of the main drive to ensure reliable performance and smooth operation. The hydraulically controlled upper guide arm is equipped with a target line locator and a mechanical sizing device, making the operation more convenient and accurate. The machine tool workbench and console are designed with escalators up and down, and are surrounded by guardrails to ensure the safety of the operator.

Features:

Small footprint: The pulley structure design minimizes the footprint and is suitable for limited work spaces.

Centralized control: Operation control is centralized on the console of the sawhorse, making operation easier and more efficient.

Adjustable feed speed: DC motor controls the feed speed, which can be adjusted arbitrarily within the range of 1-120mm/min to ensure the stability of low-speed performance.

Hydraulic control guide arm: easy to operate, ensuring the accuracy of the machining process.

Radial line locator and sizing device: conveniently and accurately align the saw edge for processing, simplifying the work clamping process.

Safety design: The workbench and console are equipped with escalators and guardrails around them to ensure the safety of the operator.

Hydraulic platform lifting: optional feeding mechanism to facilitate heavy-weight work requirements.

Flexible combination: Depending on the cutting length, single or multiple sets of platforms can be selected to improve work flexibility.

Application scenarios: G-Series multi-function pulley vertical band saws are widely used in the cutting and processing of metal, wood and other materials, and are suitable for manufacturing, construction, furniture production and other fields. Its small footprint, flexible combination, and safety and efficiency make it an ideal choice for various work scenarios.

Why choose this machine:

Efficient production: Highly centralized control design and adjustable feed speed ensure an efficient production process.

Safe and reliable: Safety design and hydraulic control make operation safer and more reliable.

Flexible application: Optional hydraulic platform lifting and flexible combination methods can adapt to different work needs.

Precise processing: The radial line positioner and length-setting device ensure the accuracy of the processing process.

Differences from machines of the same type:

Compared with machines of the same type, the G-Series multi-function pulley vertical band saw has obvious advantages in terms of floor space, operation control, feed speed adjustment, hydraulic control, and safety design. Its unique radial line locator and mechanical sizing device, as well as the optional hydraulic platform lifting function, make it more competitive in terms of application scenarios and flexibility.

Send Inquiry:

If you are looking for a trolley vertical band saw that has a small footprint, is easy to operate, is safe and reliable, the G-Series is definitely your ideal choice. We welcome you to contact us at any time to learn more about product performance and customized services. Click the link below or call our customer service, we will be happy to provide you with a satisfactory solution.

Learn more about sawing machines: [https://www.barpeeling.com/juchuang/]

Contact information: [ liu@mingchenggroup.com ]

By choosing us, you will usher in a new experience of efficient production and precise processing. We look forward to tailoring the most suitable cutting solution for you!